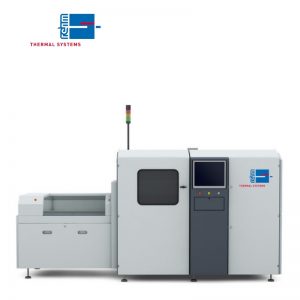

Product description

Vapor phase soldering for high throughput

The CondensoX series is based on a well-conceived design, in particular with regard to the hermetically sealed process chamber. Without moving the PCB during the process, the CondensoXP combines vacuum profiling and temperature profiling into a single system. Since the PCBs are not moved during the process, any shifting of the components is virtually ruled out. This, as well as outstanding temperature profiling, reduces failure rates and improves total cost of ownership.

In the case of the CondensoXP variant, the loading axis is laid out such that it’s suitable for hook up to an automated loading unit. The CondensoXP HS is equipped with a second loading axis for increased throughput. The process chamber can thus be reloaded while the workpiece carrier is being cooled down at the same time. This system is perfect for use in high-speed production lines.

Features

- Ideal for processing high-mass PCBs

- Smallest possible ΔT

- Extremely effective and homogenous heat transfer over the entire PCB

- Maximum soldering temperature limited by the medium’s boiling point

- A patented injection process assures reproducible soldering results and permits ideal profiling

- Void-free soldering thanks to vacuum option for best possible results

- Gradient control

- No time lost with profiling

- Outstanding retraceability of all processes with wireless profiling system (WPS)