אודות חברת ASI

חברת ASI מובילה בתחום אספקת מערכות מתקדמות, ציוד, חומרים ופתרונות מקצועיים לתעשיית ההרכבות האלקטרוניות.

מעבר לפתרונות חדשניים ואמינים המותאמים לצרכי הלקוח, אנו שמים דגש על שרות מקצועי ללא פשרות ויושרה.

חברת ASI מתמחה בהקמת מפעלי הרכבות אלקטרוניות וקווי SMT על כל מרכיביו.

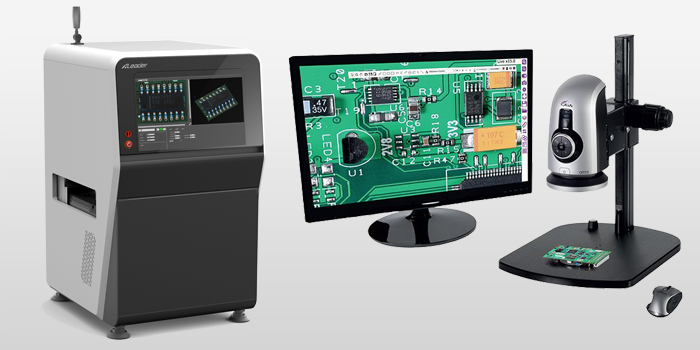

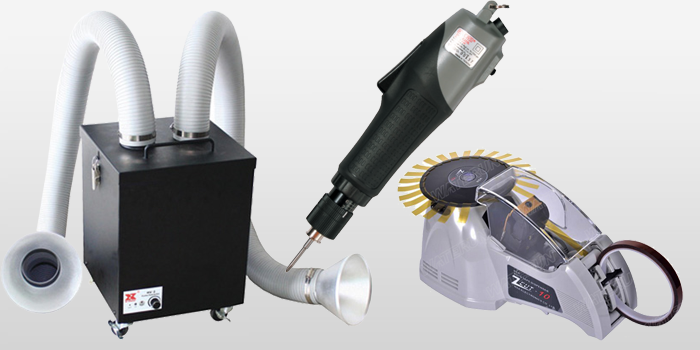

מגוון המוצרים האיכותיים שאנו מציעים כולל בין היתר מכונות להשמת רכיבים, מדפסות SMT ,מערכות בדיקות אופטיות,(SPI/AOI) עמדות תיקונים, ניקוי כרטיסים וסטנסילים, פרופיילרים, הלחמה סלקטיבית, רובוטים להלחמה, דיספנסרים ומכונות ציפוי, מסועים ומערכות שינוע מעגלים, ארונות ותנורי יבוש ומגוון רחב של כלי עבודה, חומרי הלחמה, חומרי ניקוי מתקדמים וחומרים מתכלים. כל מה שנדרש למפעל מתקדם ויעיל !